Fall Arrest Lifeline Solutions: Ensuring Safety in the Philippines & Asia

In industries across the Philippines and Asia, ensuring the safety

In the bustling industries of the Philippines, efficiency and safety are paramount concerns. Lifting operations, whether in construction, manufacturing, or logistics, demand precision and reliability to ensure both worker safety and operational productivity. Automatic hooks emerge as a solution to these challenges, offering a range of benefits that cater to the unique needs of the Philippine market.

Safety remains a top priority in lifting operations across the Philippines. With the bustling activity in construction sites and industrial facilities, the risk of accidents looms large. Automatic hooks address this concern with advanced electronic features such as load sensors and automatic locking mechanisms. By eliminating the need for manual intervention during lifting, they mitigate the risk of accidents caused by human error, ensuring a safer working environment for all.

Efficiency is the cornerstone of success in Philippine industries. Time is money, and any delays in lifting operations can have cascading effects on project timelines and costs. Automatic hooks streamline these operations with features like remote control operation and automatic release. Operators can load and unload materials swiftly and effortlessly, saving precious time and resources in the process.

The Philippine landscape presents diverse working conditions, from cramped spaces to rugged terrains. Automatic hooks prove their versatility by seamlessly adapting to these environments. Whether it’s navigating confined spaces or lifting loads on uneven surfaces, these hooks offer a solution for every scenario. Their ability to accommodate different load sizes and shapes makes them indispensable tools across various industries.

Downtime is the bane of productivity in any industry. In the fast-paced world of Philippine business, every minute lost to maintenance or equipment failure translates to lost opportunities. Automatic hooks boast unmatched durability and reliability, minimizing downtime and maintenance costs. Built to withstand harsh environments and heavy use, they ensure consistent performance, keeping operations running smoothly.

Worker safety and well-being are non-negotiable in the Philippine workplace. Manual lifting and pulling can take a toll on operators, leading to musculoskeletal injuries and discomfort. Automatic hooks alleviate this strain with their ergonomic design. By enabling remote control operation, they eliminate the need for manual exertion, promoting better ergonomics and reducing the risk of workplace injuries.

Data-driven decision-making is gaining traction across Philippine industries. Automatic hooks offer advanced data monitoring capabilities that allow operators to track and analyze lifting operations. This data can be leveraged to optimize processes, monitor load weights, and ensure compliance with safety regulations. 828 Cable System Inc. By harnessing the power of data, businesses can enhance operational efficiency and safety standards.

Hazardous environments pose significant risks to workers in the Philippines. Whether it’s extreme temperatures or hazardous materials, ensuring operator safety is paramount. Automatic hooks come equipped with remote operation capabilities, allowing operators to control lifting operations from a safe distance. This minimizes the risk of accidents and injuries, ensuring the well-being of workers in challenging environments.

The era of Industry 4.0 brings with it a wave of technological advancements that revolutionize traditional industries. Automatic hooks seamlessly integrate into Industry 4.0 systems, enabling data exchange and communication with other smart devices and systems. This integration enhances coordination and synchronization of lifting operations, leading to increased automation, efficiency, and productivity.

Automatic hooks emerge as a game-changer in the landscape of lifting operations in the Philippines. By prioritizing safety, efficiency, and adaptability, these innovative devices cater to the diverse needs of Philippine industries. As businesses embrace automation and technological advancements, automatic hooks pave the way for smarter, safer, and more productive lifting operations across the country.

In industries across the Philippines and Asia, ensuring the safety

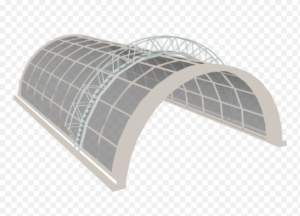

In today’s architecture and urban planning, greening solutions play a

In today’s fast-paced world of construction and maintenance, efficient access

In industries where working at heights is commonplace, ensuring the

In workplaces where heights are involved, ensuring safety against falls

In the realm of modern architecture, the integration of innovative

Copyright © 828 Cable System Inc. Philippines 2023 All Right Reserved